Power & Steam Generation System

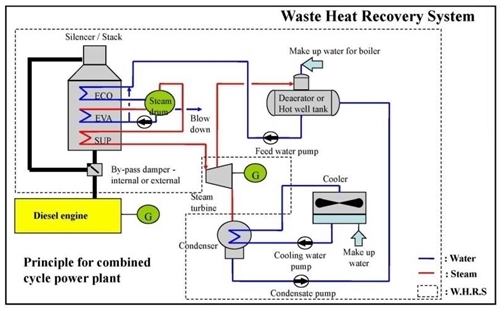

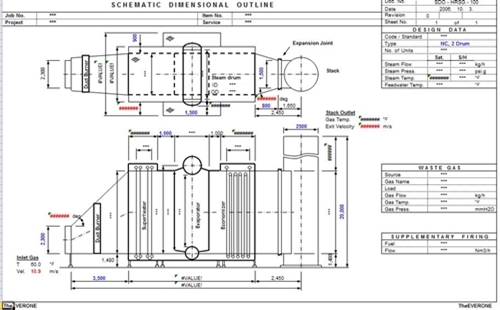

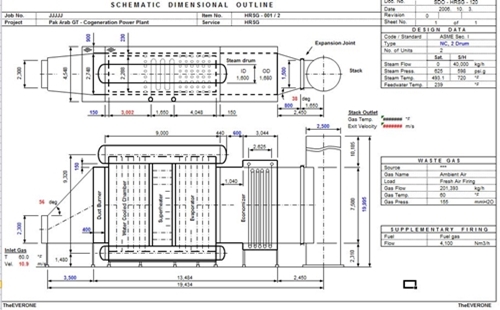

Waste Heat Recovery System

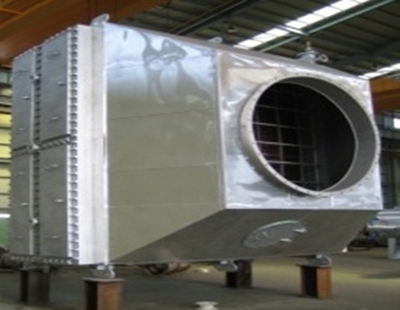

1) Water Tube Boiler

- Low to high steam capacity, 1 - 100 t/h

- Low to high pressure, up to 100 bar

- Low weight

- Quick response to load changes

- Short start up period

- Require softened feed water

- Possible to clean during operation

- Possible to install internal by-pass

Water Fin Tube – Rectangular Type

2) Smoke Tube Boiler

-

Low to medium steam capacity,

typical 0.2 - 30 t/h - Low pressure, up to 25 bar

- Heavy (high water content)

- Medium response to load changes

- Long start up period

- Water quality less critical

- Not possible to clean during operation

- Not possible to install internal by-pass

Smoke Tube Boiler System

- Project : BRIKAMA II POWER

- End User : Gambia Government.

- Client : STX Heavy Industries Co., Ltd.

- Material : SA516-70

- Boiler Size : t12/t12 x I.D1,826 x L5,000

- Design Pressure : 11/5 Bar.G

- Output : 1.0 T/hr x 2set

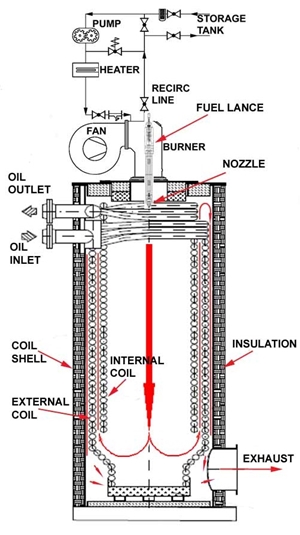

3) Thermal Oil Boiler

Thermal oil boiler can be delivered with capacity up to 5000kW.

With our system can be included Exh. Gas Thermal Boiler.

In case of thermal boiler can be designed fin tube type or bare tube type

We can supply in the form of package for auxiliary equipment.

(circulation pump and expansion tank, storage tank, etc.).

Therefore, we provide more smaller installation area, easier installation work.

Thermal Oil Heater

- Project : MOE IRAQ

- End User : IRAQ Government.

- Client : STX Heavy Industries Co., Ltd.

- Material : SPPS370

- Boiler Size : O.D1,600 x L3,400 x 6set

- Design Pressure : 9 Bar.G

- Output : 1200 KW

Thermal Oil Heating System

- Project : PARIT BARU 20MW

- End User : Jakarta city in Indonesia

- Client : PT. Arena Maju Bersama

- Material : SA516-70

- Boiler Size : O.D2,500 x L5,400 x 2set

- Design Pressure : 3 Bar.G

- Output : 2000 KW

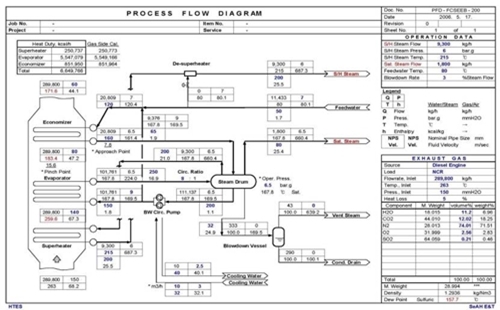

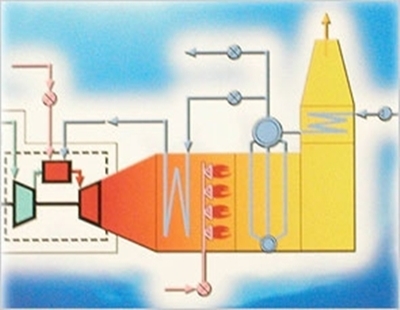

Heat Recovery Steam Generator System

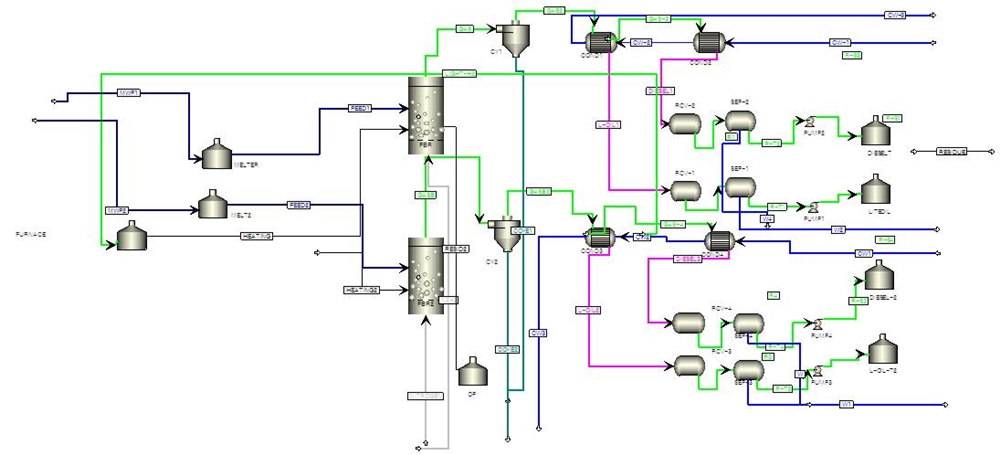

Waste Plastic Pyrolysis Plant

Waste Plastic Pyrolysis Plant exists for converting waste plastics, including handbags, bottles, and films into energy through the waste pyrolysis technology. With the waste pyrolysis technology, you can process waste plastic to fuel oil, carbon black and combustible gas. The machine subjects the waste plastics to very high temperatures and oxygen-free conditions to produce the three products. Furthermore, this plastic recycling plant helps eliminate pollution. In addition, you will actually get profits while reducing environmental pollution.

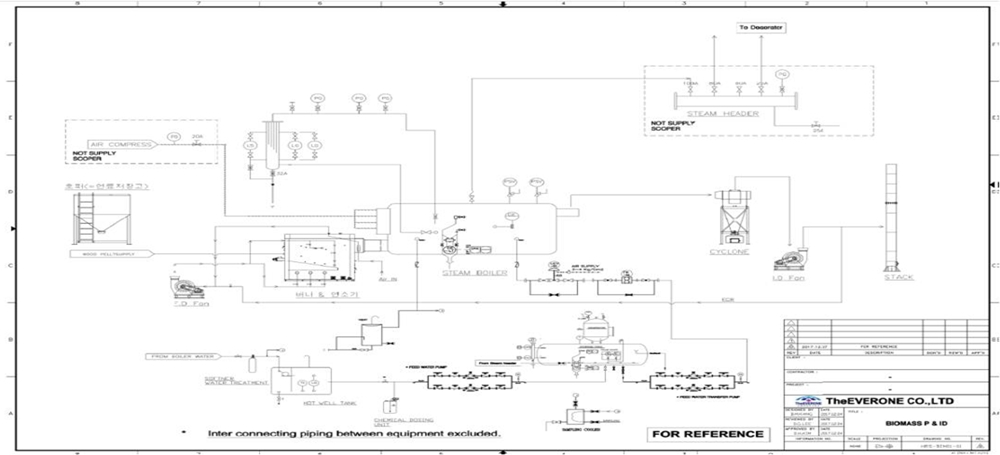

Biomass Power Generation

Biomass boiler is defined as a biomass fuelled heating system.

It generates heat by burning agriculture & forest residues, burn logs, wood pellets and others.

It majorly produces heat by burning wood. Biomass boilers are widely used by hotels, farms, households and others. Further, biomass boiler helps to lower down the greenhouse gas emission due to their low carbon footprints.

Organic Rankine Cycle

- Project : Young-Kwang ORC 250KW

- End User : Young-Kwang Co., Ltd.

- Client : Young-Kwang Co., Ltd.

- Material : SA516-70

- Total Size : W2,800 x H3,500 x L12,050

- Design Pressure : 25 Bar.G

- Fluid : Refrigerant R245-fa

- Output : 250 KW

The Organic Rankine Cycle's principle is based on a turbo generator working as a conventional steam turbine to transform thermal energy into mechanical energy and finally into electric energy through an electrical generator. Instead of generating steam from water, the ORC system vaporizes an organic fluid, characterized by a molecular mass higher than that of water, which leads to a slower rotation of the turbine, lower pressures and no erosion of the metal parts and blades.

Air Cooled Condenser

Air Cooled Condenser is a method of cooling refrigerant by sending it to the pince way and sending air to the outside of the fan.

We can supply in the form of package for auxiliary equipment

(Circulation pump and Tank, Piping, Etc.).

Therefore, we provide more smaller installation area, easier installation work.

- Project : Waste Heat Energy Recovery

- End User : SAMYOUNG E&E

- Client : Korea Engineering Consultants Corp.

- Material : SA516-70

- Total Size : W11,600 x H8,000 x L19,050

- Design Pressure : 10 Bar.G

Steam Accumulator

- Project : Steam Accumulator Installation

- End User : Solvay Chemicals Korea Co., Ltd.

- Client : SPIRAX SARCO

- Material : SA516-70

- Total Size : t30/t36 x I.D3,000 x L17,000

- Design Pressure : 25 Bar.G

Steam Generator, Preheater(stacked type), Tank

- Project : Steam Generation System

- End User : PUNGGUK Ethanol

- Client : SPIRAX SARCO / HAN SARCO Engineering

- Material : SA516-70 / SA516-70 / STS304

-

Size

: t14/t16 x I.D2,100 x L8,234

: t10/t10 x I.D580 x L5,220

: t10/t10 x I.D1,100 x L2,500

: t8/t10 x I.D2,200 x L3,000 - Design Pressure : 25 Bar.G

Feed Water Heater

- Project : Feed Water Heater

- End User : Namdong National Industrial Complex

- Client : ERG Service

- Material : SPPS380

- Size : t9.5 x I.D406.4 x L3,050 x 2set

- Design Pressure : 20 Bar.G